In today’s competitive beverage industry, understanding the nuances of green bean roasting is essential for businesses looking to produce high-quality coffee. This article aims to provide an in-depth guide on simple green bean roasting, highlighting its importance in enhancing the flavor profile of coffee.

By starting with the raw form of coffee, businesses have the opportunity to develop their own unique roasting process that can lead to superior and consistent results.

The discussion will also include critical insights into common practices and techniques, ensuring that even those who are new to the process can quickly gain a comprehensive understanding of how to achieve the best outcomes.

Moreover, readers will gain insight into how properly roasted green beans contribute to a balanced and robust coffee experience, aligning with the strict quality standards required in the business-to-business market.

Inhaltsübersicht

Umschalten aufGreen bean roasting is the process by which unroasted green coffee beans are transformed into the aromatic, flavor-rich product used to brew coffee. This transformation is achieved through the application of heat, which initiates a series of chemical and physical changes.

During green bean roasting, the internal structure of the beans is altered, developing complex flavors and aromas that are not present in their raw state. A thorough understanding of the roasting process is critical because it allows businesses to control the flavor profile of the final product.

The process involves carefully managing variables such as temperature, time, and airflow to ensure that the beans achieve the desired level of development. Improper control can lead to over-roasted or unevenly roasted green beans, whereas proper technique results in consistently roasted green bean profiles.

The concept of green bean roasting encompasses more than just the physical act of applying heat. It also involves understanding the chemical reactions that occur within the bean, such as the Maillard reaction and caramelization.

These reactions are responsible for producing the desirable flavors and subtle variations that differentiate one batch of roasted green bean from another. This knowledge is essential not only in enhancing flavor consistency but also in innovating new roasting techniques that can cater to specific market demands in the B2B sector.

Roasting green coffee beans is a critical process that brings out the unique flavor characteristics that define the quality and appeal of the final beverage. By subjecting the raw beans to controlled heat, businesses can significantly enhance the coffee’s aroma, body, and flavor complexity.

When executed correctly, green bean roasting results in roasted green beans that exhibit a distinctive profile ideal for high-end coffee products, setting a benchmark in the competitive beverage industry.

Roasted green bean profiles are influenced by the nuances of the roasting process. Factors such as the duration and intensity of the heat application play a pivotal role in determining whether the beans develop a light, bright taste or a heavier, more robust flavor.

For instance, a shorter roasting period may yield a mild and acidic profile, while a prolonged process can enhance bitterness and deepen the overall flavor. This versatility allows companies to tailor their roasting protocols to meet specific customer preferences and market demands.

In addition to flavor development, the roasting process affects the chemical composition of the coffee beans. Through controlled heat exposure, the natural sugars within the beans undergo reactions that transform them into complex flavor compounds.

These reactions are critical in achieving consistent and high-quality roasted green bean results. An in-depth understanding of the factors that influence these changes is essential for ensuring that every batch meets the rigorous quality standards expected by B2B partners.

Moreover, roasting green coffee beans in-house can serve as a strategic differentiator in the market. It allows companies to optimize their product offerings by customizing roast levels to highlight unique flavor notes, thereby creating a signature coffee blend that resonates with discerning clients.

This not only reinforces brand credibility but also supports a competitive edge in a market that values quality and consistency.

To ensure a successful green bean roasting process, it is essential to have the appropriate tools and high-quality ingredients. The efficiency and precision of the process can be greatly enhanced when the right equipment is utilized alongside premium green coffee beans.

1. Roasting Machine

A reliable roasting machine is critical. Whether using a fluid-bed roaster or a drum roaster, the equipment must offer precise control over temperature, airflow, and roasting time. This ensures that each batch of roasted green beans achieves the desired profile.

2. Thermometer and Timer

Accurate measurement tools such as digital thermometers and timers are indispensable for maintaining consistency during the roasting process.

These instruments help monitor the temperature changes and roasting duration, which are crucial for the transformation of green coffee beans into a well-developed roasted green bean product.

3. Cooling Tray

After the roasting is complete, a cooling tray or a cooling tunnel is necessary to quickly and effectively bring down the temperature of the beans. This rapid cooling helps preserve the flavors developed during the green bean roasting process and prevents over-roasting.

1. High-Quality Green Coffee Beans

The foundation of an excellent roasted green bean is the quality of the raw beans. Sourcing premium green coffee beans is vital, as they serve as the primary ingredient that will undergo the green bean roasting process.

The selection criteria should focus on factors such as bean origin, freshness, and varietal characteristics.

2. Optional Additives

Although not necessary, some roasters may choose to incorporate natural additives such as spices or organic flavors to create a signature profile. However, maintaining the integrity and natural taste of the roasted green bean is often a priority in a professional setting.

1. Maintenance Tools

Regular maintenance of roasting equipment is essential. Accessories like cleaning brushes, spare parts, and routine maintenance kits help ensure the longevity and efficiency of the machinery, contributing to a consistent roasting process.

2. Data Logging Devices

For industrial-scale operations, integrating data logging devices can aid in tracking and analyzing the roasting parameters over time. This data is invaluable for refining the green bean roasting process and ensuring reproducible quality.

Ensuring that these tools and ingredients are at hand will provide a solid foundation for a predictable and high-quality green bean roasting process. The precision of this approach not only enhances the final product quality but also supports operational efficiency and brand reliability in the competitive B2B market.

The green bean roasting procedure is a systematic approach that requires precision and attention to detail to achieve a consistently high-quality result.

Each step in the process contributes to the transformation of unroasted green beans into flavorful, roasted green beans that are ready for brewing. The following steps provide a comprehensive guide to executing an effective green bean roasting process:

1. Preheating the Roaster

Begin by preheating the roaster to the target temperature suitable for green bean roasting. Preheating ensures that the green coffee beans are exposed to a consistent heat right from the start.

This step is critical because any fluctuation in temperature at this early stage could compromise the uniform development of the roasted green bean.

2. Loading the Green Coffee Beans

Once the roaster has achieved the desired temperature, carefully load the high-quality green coffee beans.

It is important to ensure an even distribution of beans to facilitate an identical heat exposure throughout the batch. This step sets the stage for uniformity, which is vital in producing evenly roasted green beans.

3. Initiating the Roasting Process

Start the roasting process by activating the roasting mechanism. During this phase, monitor the temperature, airflow, and timing meticulously.

As the process unfolds, chemical reactions such as the Maillard reaction and caramelization begin to occur inside the beans, gradually developing the roasted green bean profile. Maintaining accurate measurements throughout this step is essential for consistent quality.

1. Monitoring Development Stages

Continuous observation is necessary to identify key development milestones, such as the first crack—a critical phase in the green bean roasting process where the beans expand and emit distinct sounds.

This stage signals the beginning of the transformation, and the roasting process should be adjusted depending on whether a light, medium, or dark roast is desired. Detailed monitoring ensures that the roasted green bean reaches the targeted flavor and aroma.

2. Cooling the Roasted Green Beans

Once the desired roast level is achieved, immediately transfer the beans to a cooling tray to arrest the roasting process.

Rapid cooling is essential to lock in the flavor and prevent further reaction, thus preserving the characteristics of a perfect roasted green bean. A well-executed cooling process is critical for retaining both the aroma and the overall quality of the final product.

3. Post-Roasting Evaluation

After cooling, conduct a thorough evaluation of the roasted green beans. This evaluation includes examining the uniformity, aroma, and overall taste profile.

Adjustments to the roasting parameters may be made based on feedback from this evaluation to ensure that future batches meet the stringent quality standards required by the market. This continuous improvement cycle is central to refining the green bean roasting process.

In this structured approach to green bean roasting, every step is managed carefully to yield a final product that meets the rigorous demands of today’s coffee industry. The detailed control over each phase, from preheating to post-roast evaluation, ensures that each batch of roasted green beans is consistent and of superior quality.

Achieving an impeccable roast of green coffee beans requires precision, adaptability, and continual refinement of techniques. In this section, we outline several practical tips and insider tricks to ensure that your green bean roasting process consistently produces a superior quality product.

1. Consistent Bean Sourcing

Ensure that you use high-quality, consistent green coffee beans. Variations in bean quality and moisture content can affect the outcome of your roast. Maintaining reliable suppliers guarantees that each batch of roasted green beans meets your standards for flavor and consistency.

2. Pre-Roast Calibration

Invest time in calibrating your equipment before commencing the roasting process. Regular calibration of temperature controls, thermometers, and timers is essential to achieve the precise heat application needed for an optimal roast.

This proactive measure helps avoid discrepancies in the heat distribution, which directly impacts the final flavor of the roasted green bean.

3. Monitoring Roast Profiles

Employ data logging tools or manual tracking of roast profiles. Recording variables such as temperature curves, development time, and roast levels allows for the identification of any deviations from the expected outcome.

This documentation is vital for refining your processes and ensuring repeatable, reliable results across different batches.

4. Adjusting Roasting Parameters

Be prepared to adjust roasting parameters in real time. Factors such as ambient humidity, bean moisture content, and even the age of your equipment can affect the roast.

Regular adjustments during the process can help in achieving a balanced roasted green bean profile that suits the desired flavor profile. In particular, the moment just before the first crack and during the development stage can serve as critical points for fine-tuning your roast.

5. Leveraging Expert Sensory Evaluation

Utilize expert sensory evaluation in your quality control procedures. Tasting panels or in-house experts can help determine if a roast meets the desired flavor, aroma, and body criteria.

Their feedback should inform adjustments for subsequent batches, creating a cycle of continuous improvement and ensuring every batch of roasted green bean ultimately meets the target quality standards.

6. Optimizing Cooling Techniques

Rapid and uniform cooling is paramount. A well-designed cooling phase protects the intricate flavor profile developed during the roasting process.

Invest in high-quality cooling equipment or systems to ensure that the roasted green bean is effectively arrested at the precise moment, thereby preserving the optimal aroma and taste profile.

7. Experimentation and Innovation

Finally, maintain a culture of experimentation. While consistency is key, controlled experiments with minor variations in the roasting process can lead to new flavor profiles or insights into optimizing your process.

Keeping detailed records of these experiments, including their sensory and technical results, will support long-term process innovation and help your business stay competitive in the B2B market.

Each of these tips contributes to the creation of roasted green beans that not only meet but exceed industry standards. By focusing on precision, continual monitoring, and responsive adjustments, businesses can achieve a consistently high quality that will delight even the most discerning clients.

In the pursuit of achieving consistently superior roasted green beans, it is crucial to recognize and avoid several common pitfalls associated with green bean roasting. Identifying these mistakes early in the process can prevent batch inconsistencies and ensure that the final product meets the rigorous expectations of your B2B clientele.

1. Inadequate Preheating

Failing to properly preheat the roaster can lead to uneven green bean roasting. Insufficient preheating causes fluctuations in temperature at the beginning of the process, which may result in underdeveloped or overdeveloped roasted green bean profiles.

2. Overloading the Roaster

Loading excessive quantities of green coffee beans into the roaster disrupts even heat distribution. Overcrowding the roasting chamber can prevent the beans from roasting uniformly, resulting in a mixture of under-roasted and over-roasted green beans within the same batch.

3. Ignoring Moisture Content Variability

Green coffee beans inherently vary in moisture content based on their origin and processing method. Neglecting to adjust the roasting parameters according to these differences can adversely affect the outcome. Uniformity in the roasted green bean product is best achieved by properly accounting for such variations.

4. Poor Temperature and Time Management

Inconsistent temperature control and inaccurate timing are common causes of quality discrepancies. Relying on outdated equipment or manual approximations can disrupt the precision needed for optimal green bean roasting.

This often leads to roasted green bean profiles that do not align with the intended flavor and aroma goals.

5. Insufficient Monitoring During Development Stages

Failure to closely monitor key milestones such as the first crack can result in missing critical cues during the roasting process. This oversight may lead to either premature or delayed cooling, which significantly impacts the final quality of roasted green bean flavor and consistency.

6. Inadequate Cooling Procedures

A sluggish or ineffective cooling process can cause the beans to continue cooking, thereby diminishing the integrity of the intended roast profile.

Ensuring rapid cooling is critical to preserve the specific characteristics of the roasted green bean and to halt the ongoing chemical reactions promptly.

7. Neglecting Routine Equipment Maintenance

Over time, equipment performance can decline without regular maintenance. Failure to service roasting machines, thermometers, and other critical tools may lead to unpredictable outcomes and impair the overall consistency of the green bean roasting process.

By proactively addressing these common mistakes, businesses can mitigate risk and streamline the production of consistently high-quality roasted green bean batches. This attention to detail not only enhances the flavor profile of the final product but also reinforces operational reliability in a competitive market.

Achieving a consistent and high-quality roasted green bean product is essential for establishing a reliable reputation in the competitive B2B coffee market. A systematic approach to quality control during the green bean roasting process can ensure that every batch meets strict industry standards.

1. Standardized Roasting Protocols

Developing and adhering to standardized roasting protocols is a fundamental step towards consistency.

Detailed documentation of temperature curves, roast durations, and cooling times can help eliminate variability between batches. By following these protocols, businesses can reliably produce roasted green beans with a predictable flavor profile.

2. Regular Equipment Calibration and Maintenance

Consistency in green bean roasting is highly dependent on the performance of the equipment. Regular calibration of roasting machines, thermometers, and timers is crucial to maintain precise control over the process. Scheduled maintenance not only extends the lifespan of the equipment but also minimizes potential fluctuations during each roast cycle.

3. Quality Control Checkpoints

Incorporating quality control checkpoints throughout the roasting process is essential. These checkpoints can include monitoring the first crack, assessing the progression of the roast, and measuring the color and aroma of the beans.

Implementing routine sensory evaluations—such as cupping sessions—provides immediate feedback on the quality of the roasted green bean, helping to identify any deviations and allowing for quick corrective actions.

4. Data-Driven Process Optimization

Utilizing data logging tools and analytics enables a comprehensive understanding of the green bean roasting process. By continuously collecting data on temperature, airflow, and roast development, businesses can refine their processes over time.

This data-driven approach not only reinforces consistency but also facilitates innovation, leading to the development of new roasted green bean profiles that meet evolving market demands.

5. Training and Team Expertise

Investing in ongoing training for the roasting team is vital. A well-trained team that understands both the technical and sensory aspects of green bean roasting can better implement quality control measures.

Continuous education on the nuances of green coffee bean behavior during roasting enhances team capability, ensuring that each batch of roasted green bean is produced with expert precision.

By focusing on these practices, companies can produce roasted green beans that consistently deliver the expected quality and flavor.

This commitment to quality and consistency not only supports operational efficiency but also underpins customer satisfaction and long-term business relationships in the B2B marketplace.

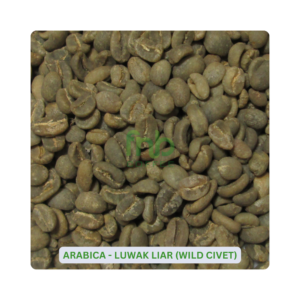

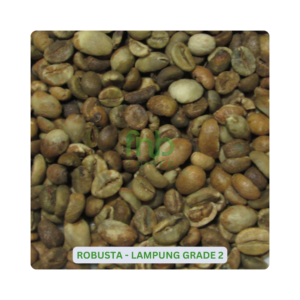

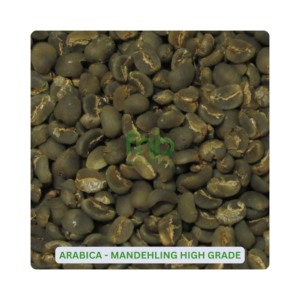

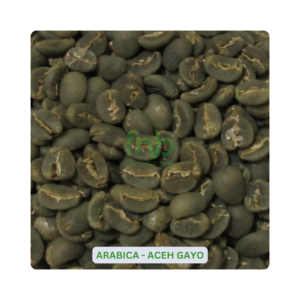

FnB Coffee offers a diverse selection of premium green coffee beans designed to meet the specific requirements of your green bean roasting process. Our commitment to quality and variety ensures that your business has access to the finest beans available in the market. Here’s an overview of what we provide:

1. Wide Range of Coffee Varieties

2. Arabica Coffee:

3. Our Best Seller Products

By offering this comprehensive selection, FnB Coffee ensures that your business can consistently produce high-quality roasted coffee. Our transparent sourcing and rigorous quality control provide a reliable foundation for your coffee production process..

Ready to elevate your green bean roasting operations? FnB Coffee invites you to experience the difference that premium-quality green coffee beans can make.

Our team is dedicated to providing B2B clients with dependable access to fresh, carefully sourced beans that serve as the foundation for consistently excellent roasted green bean batches.

Ordering from FnB Coffee is seamless and tailored to your business needs. Whether you require a small trial batch or a large-scale supply, we offer scalable solutions that ensure you never compromise on quality.

Our streamlined procurement process, transparent pricing, and responsive customer support make us the ideal supplier for roasters, coffee shops, wholesalers, and specialty retailers.

Don’t settle for inconsistent or inferior beans—choose a supplier that understands the precise requirements of green bean roasting and is committed to helping your business succeed.

Contact FnB Coffee today to learn more about our available selections or to place your first order. Experience firsthand why so many businesses trust us for their green coffee sourcing needs.

Sind Sie daran interessiert, indonesische Rohkaffeebohnen zu kaufen? Rufen Sie uns an WhatsApp Jederzeit unter +62 811 6171 777 oder E-Mail info@fnb.coffee

FnB Coffee Indonesia ist auf den Großhandel mit indonesischen Rohkaffeebohnen spezialisiert. Wir konzentrieren uns auf den Business-to-Business-Großhandel und den Massenvertrieb, um sicherzustellen, dass unsere Kunden weltweit nur die besten indonesischen Kaffeebohnen erhalten.

© 2025 Copyright FnB Coffee Indonesia, Alle Rechte vorbehalten.

Büro Jakarta

Gedung Menara Sentraya, lantai 39, Jl. Iskandarsyah Raya No. 1A Kel. Melawai, Kec. Kebayoran Baru, Jakarta Selatan 12160.

Lagerhaus

Jl Medan - Binjai. Mulyorejo

Kec. Sunggal, Kabupaten Deli Serdang

Sumatera Utara. 20351

Bepflanzung

Boangmanalu Salak

Kec. Salak, Kabupaten Pakpak Bharat

Sumatera Utara. 22272

Plan zur Verarbeitung von Spezialitätenkaffee

Desa Pondok Balik

Kec. Ketol, Kabupaten Aceh Tengah,

Aceh. 24566

Rufen Sie uns an

+62 811 6171 777

info@fnb.coffee